Knowledge

Come-on, there’s no comparison …

There is no comparison in the level of safety and the ability to control emissions of hazardous chemicals, between a well designed Bellows Seal globe valve and your standard ball and plug valves. Any chemical producer who wants to have the safety of its workers at the top of its agenda, should always be looking to fit the best possible protection against all leaks of dangerous hazardous chemicals. Bellows Sealed Valve design have been accepted as the best practical method for ensuring repeatable tight shut off and preventing leaks via valve spindles and body joints. There are good reasons why Eur Chlor members use Bellows Seal Globe Valves.

When you can have this…..

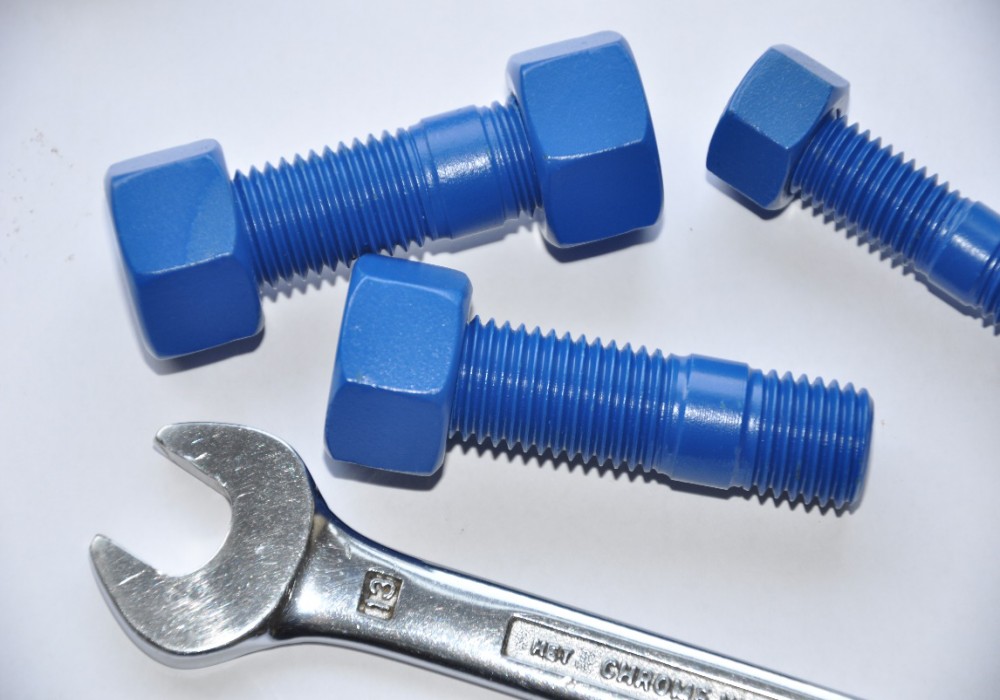

When you design and manufacture products that last and can be maintained to enable additional years of service, then it makes sense to ensure that the correct bolting can removed without damaging the valve body flanges. In the hazardous chemical sector it can be a corrosive environment. Untreated or poorly treated barrier corrosion won’t prevent severe build up of surface damage to bolts, studs and nuts, making them very difficult to remove. At Hunt & Mitton we have been treating our connectors with a Xylan® self lubricating coating, to ensure that corrosion is kept to a minimum and that body parts can be undone for critical inspection and repair if necessary. All of our valves being used on hazardous chemical applications have connectors treated with highly effective self lubricating anti corrosion barrier protection.

Hunt & Mitton has come a long way…..

We have come a long way since developing the original Hunt & Mitton hazardous chemical valves in the 1950s with ICI. We have improved our designs with modern materials, a deep understanding of chemical and material compatibility and control valve expertise. We have built a strong and experienced European management team who have assembled a highly skilled manufacturing team in China. Our design, supply chain and manufacturing processes have been independently assessed by European third party inspection agencies resulting in Euro Chlor approval for our bellows seal globe valves. We have surpassed the highest level of requirements in casting integrity and our product sales are growing to blue ribbon chemical producers in Europe, Americas and Asia. We have achieved all of this whilst offering great service to our customers and partners.

What’s more … we are enjoying the journey.

The Cost of Just 1 hour lost …….

One of the most common problems faced by plant operators in the hazardous chemical sector is isolating valves that don’t shut off when required. While there are many reasons that can cause this fault, one of them should never be due to the choice of valve design or poor choice of materials. When pipelines or pump skids cannot be safely isolated, it can lead to lost production time. Just 1 hour lost production equates to 100s of times of the difference in cost of a Bellows Seal Globe Valve versus an inferior design of shut off valve. Be money smart and fit Euro Chlor approved Bellows Seal Globe Valves which will outperform other designs repeatedly for many years.